Titanium Blog

RSS

-

FINISHMASTER 5TH ANNUAL TRADESHOW - MANITOBA

Read nowWelcome. Thank you for stopping by and checking out Titanium Tools and Equipment's offerings. By scanning a quick QR code (available on our table during the show), you can unlock special promotions that are exclusively available to FinishMaster show attendees. Don't miss out on these unique offers!

-

From Welding to the Auto Industry: A Journey of Precision and Growth

As I work towards my goals of delivering exceptional service, becoming an i-car welding instructor, and helping to create and administer courses in our training centre, I am excited to see what the future holds for me and the outstanding team at Titanium Tools and Equipment. Together, we will continue to push the boundaries of welding excellence, ensuring that our customers receive the highest quality workmanship and service.Read now -

Is it Time to Replace Your Spot Welder? Factors to Consider

As you evaluate your spot welder's lifespan and usage frequency, the decision to budget for a replacement becomes clearer. Upgrading to a newer model not only introduces advanced features and automation but also ensures compliance with industry certifications and offers improved service and support. Remember to explore trade-in options, consider a service contract for proactive maintenance, and choose a reputable supplier who can cater to your specific needsRead now -

Achieving Flawless Spot Weld Removal: The Key to Consistent Results

Achieving flawless spot weld removal is crucial in collision repair, and the choice of tools and techniques dramatically impacts the outcome. By embracing spot weld cutting with specialized tools like the Wielander and Schill Vario Drill WS90 and the Dent Fix Spot Annihilator DF-15DX, technicians can deliver consistent, repeatable results that align with OEM requirements. Alternatively, implementing the tips provided ensures a smoother process when traditional drilling is the only option.Read now -

Resistance to Change

This type of mentality is prevalent in the Bodyshop industry, and I see it all the time during training and while doing service. The fantastic thing is, generally, their entire attitude toward it changes once I have shown them how to use the equipment properly. They become excited and suddenly can’t wait to try it on their next job.Read now -

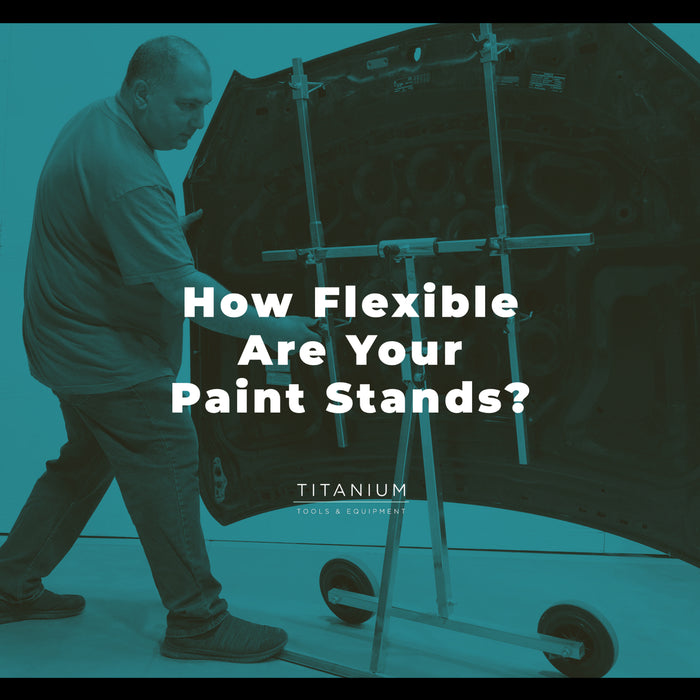

How Flexible Are Your Automotive Paint Stands?

Read nowOur Flexible Paint Stands are well-designed with large durable rubber tires that gracefully glide across shop floor surfaces with ease and never get stuck anywhere due to the size and durable design. Our stands are also able to compact into a narrow standing position saving lots of space and allowing for easy storage either up on a hanging mount or in a storage locker. All our Flexible Paint Stands are manufactured in Denmark by FK Teknik/Design and made with an electro-galvanized nickel coating which allows for easy cleaning. These are some benefits of our automotive paint stands that others do not offer.

-

Stats, Facts, & Random Thoughts - The Pilot

Read nowAfter reading Steve’s and Errol’s recent blog posts, I started thinking about the changes I have seen working within the collision industry and thought to share some facts, stats, and random info from courses I have attended. All of these plus the pressures of time - the one thing we cannot accumulate or carry forward, 86400 seconds pass daily, and once the clock strikes 12 the bank resets; onward to tomorrow and a chance to do better. Time, which we never seem to have enough each workday coupled with many changes in recent years are all factors that contribute to techs struggling with repairs on today's vehicles.

-

How To Become An Excellent MIG Welder

Quality training, combined with active participation and even the smallest amount of practice time, can hugely increase a technician’s confidence in approaching their work and also improve the quality of their repairs. This is a win for both the Body Shop and the technician as the shop is able to take on larger, more complicated repairs, and the tech is happy and confident in their ability to carry out these jobs in a profitable manner.Read now -

Journey With Sean

Read nowTitanium Tools & Equipment and the people within are tightly focused. Our products are engineered, precise, high quality, and OEM certified. We as a group are trained and committed to delivering at the same level as the products we sell.

One difference I see is that the equipment upgrades have brought OEM repair plans to the forefront, which in turn have driven shops to adapt quickly to years of OEM changes compressed into a short time frame. Less reacting, more proactivity. This has been refreshing. I'm listening to shop owners and managers who have responded in kind and are proud of it.

-

Miralce System Glue Kit

Read nowNow you can do glue repair with tools compatible with the miracle system as well as many other glue systems currently on the market today. Star company has created a glue system like no other.

This glue kit comes with various tabs of various shapes and sizes grooved to perfection to allow the glue to adhere to the tabs properly for a better grip and hold when you are doing your pulls.

-

The False Economy of Not Wiring Correctly for Your Spot Welder

In Europe, spot welders run on 440 or 400 volts but in Canada, a spot welder runs on 208 volts. This means you have a lot less power available to make a spot weld which means your welder must work harder in Canada to make an equivalent weld. If you further impact that by not providing the welder with the correct power the welder will in most cases still work but it affects the welder long term. It's like putting 89 octane in your car when it requires 93.Read now -

FORD RIVETS

A good example of this is the FORD F-150. This vehicle from FORD requires the use of NINE different sizes of Self Piercing Rivets (SPRs) and also FOUR different types of 6.5mm Blind Rivets. Unfortunately, the reality is that the responsibility to use the proper Rivets lies solely with the technician who is repairing the vehicle. The Rivets used in their repairs should always come from a FORD dealer or a supplier who has FORD Certified Rivets. Using non-approved rivets in a FORD repair can result in a multitude of problems, not least the safety of the vehicle being compromise.Read now